Weifang Ketuohong Machinery Equipment., Ltd (KTH)

Good iron casting foundry exporter full#

Dural control of standard products and OEM products.ġ) Checking the raw material after they reach our factory- Incoming quality control ( IQC)Ģ) Checking the details before the production line operatedģ) Have full inspection and routing inspection during mass production-In process quality control(IPQC)Ĥ) Checking the goods after they are finished- Final quality control(FQC)ĥ) Checking the goods after they are finished-Outgoing quality control(OQC)

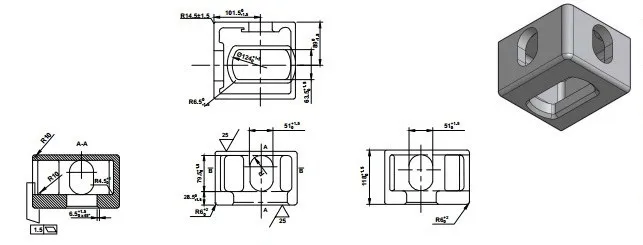

We are able to design, develop, produce and deliver your PO according to your drawings, samples or just an idea.

Good iron casting foundry exporter pro#

Our engineers are skilled at AUTO CAD, PRO ENGINEER, UG, SOLID WORKS and other 2D & 3D softwares, and we have solid mold flow software to simulate the casting process dueing tooling/die and p're design. Weifang Ketuohong Machinery Equipment., Ltd (KTH) is professional at independent development and design. MATECH policy is that none of these products will be sold to 3rd parties without written consent of the customers to whom the tooling, design and specifications belong. Please send us your detailed drawing/ sample/requirements for us offering a reasonable quotation to you and we will trying our best to make the goods in good quality and delivery in time. Products shown here are made to the requirements of specific customers and are illustrative of the types of manufacturing capabilities available within MATECH group of companies. Shot/sand blast, polishing, Primer Painting, Powder coating, ED- Coating,įinish Painting, Anodize (White or Black Color)Ĥ5 days from the receipt date of deposit for die casting part

Ra 0.8-Ra3.2 according to customer requirement

High Pressure Casting/Sand Casting, Extrusion Casting etc.ĬT4-6 for Permanent Molding, Die Casting.ģ56.0/ZL101,GAlSi7Mg (3.2371.61)/AlSi7Mg/, A-S7G, Al Si Alloy, Al Cu Alloy ZL201 Al Mg Alloy Z元01,Z元02,Īl Zn Alloy ZL401Zn Alloy Zamak 3, Zamak 5, Zamak 7, Zamak 2Ģ mm-1500mm / 0.08inch-60inch, or according to customer requirementsĬNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling/ Tapping/īroaching/Reaming /Grinding/Honing and etc. Custom Powder Coating CNC Machining Lifting Support Machinery Parts Aluminum Die Castingĭie Casting, Permanent Molding /Gravity Casting, Low Pressure Casting,

0 kommentar(er)

0 kommentar(er)